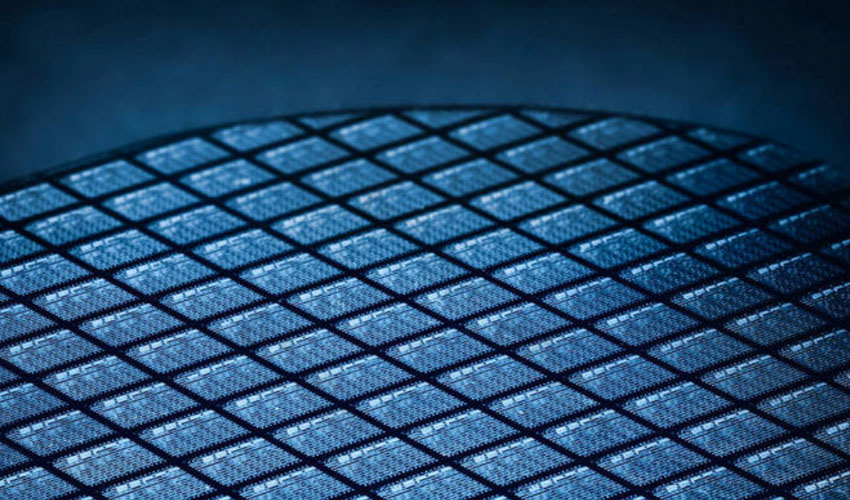

Dans le secteur de la fabrication des puces semi-conductrices, la propreté des systèmes de transport de produits chimiques ultra-purs influe directement sur le rendement des dispositifs. Les tubes PFA ultra-propres, véritables « vaisseaux d'or » de ces systèmes, sont largement utilisés.

Le PFA, ou perfluoroalcoxyalcane, est un matériau haute performance copolymérisé à partir de tétrafluoroéthylène (TFE) et d'une faible quantité d'éther vinylique perfluoroalkylé. Comparé au polytétrafluoroéthylène (PTFE) traditionnel, le PFA présente non seulement une excellente résistance à la corrosion chimique, un faible coefficient de frottement et une bonne isolation électrique (insensible à la température), mais aussi une meilleure adhérence à l'état fondu et une viscosité plus faible. Il supporte des températures élevées de 260 °C sur une longue durée, permettant ainsi la fabrication de tubes et de composants de structures complexes par des procédés tels que l'extrusion à l'état fondu.

Les matériaux PFA de haute pureté subissent de multiples étapes de transformation de précision (fusion, extrusion et moulage) pour obtenir des tubes finis. Lors de la fabrication, la micro-abrasion des pièces métalliques des équipements, les particules en suspension dans l'environnement et les fluctuations des paramètres de processus peuvent engendrer de nouvelles sources de pollution. Il est donc essentiel de vérifier la pureté des tubes PFA ultra-purs.

L'industrie des semi-conducteurs impose des exigences de pureté extrêmement élevées aux tubes PFA ultra-propres. Par conséquent, elle recourt généralement à des tests d'extraction accélérés dans des conditions extrêmes pour évaluer la fiabilité du produit.

Vérification du diamètre intérieur, du diamètre extérieur, de l'épaisseur de la paroi, de l'excentricité, de la régularité de la surface, du brillant (absence d'impuretés, de pliures ou d'abrasions) et de la conformité de l'emballage.

Actuellement, les fluoroplastiques ultra-purs jouent un rôle irremplaçable dans les procédés de fabrication des semi-conducteurs. Cependant, le marché des produits PFA haut de gamme est depuis longtemps dominé par les entreprises internationales. Ces dernières années, face à la demande croissante d'autonomie de la chaîne de valeur chinoise dans le secteur des semi-conducteurs, la production locale de fluoroplastiques de haute pureté a progressivement pris son essor. Parmi les produits qui en résultent, des composants hautement standardisés tels que les tubes PFA ultra-purs constituent les premiers exemples de percées technologiques.

Grâce à une recherche et un développement indépendants continus et à une optimisation des processus, Baoshili a réussi à produire Tubes PFA ultra-propres Ces produits répondent aux exigences des procédés de fabrication de semi-conducteurs de pointe. Ils ont progressivement intégré les chaînes d'approvisionnement de plusieurs grands fabricants de puces, offrant ainsi une voie concrète pour favoriser le remplacement des matériaux haut de gamme par des matériaux nationaux.

un service en ligne

un service en ligne +86 592 625 8655-ext-622

+86 592 625 8655-ext-622 carrie@xmbsl.com

carrie@xmbsl.com carrielin36

carrielin36 +8613850062482

+8613850062482